- Homepage

- Uncategorized

- Japanese POWs Scoffed at Thin American Blankets — Until They Saved Them from the Cold. VD

Japanese POWs Scoffed at Thin American Blankets — Until They Saved Them from the Cold. VD

Japanese POWs Scoffed at Thin American Blankets — Until They Saved Them from the Cold

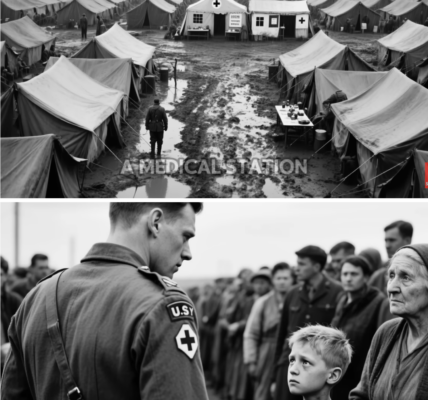

The Blanket of Truth

December 3rd, 1943. The wind howled across the barren plains of Camp Concordia, Kansas, as Lieutenant Hiroshi Tanaka stood shivering, despite the wool blanket draped around his shoulders. Just three weeks earlier, he had been captured in the Marshall Islands after a devastating American naval bombardment left his unit stranded and surrounded. Now, standing in this prisoner of war camp in the heart of America, Tanaka stared in disbelief at the thin blanket he had been issued upon arrival, his fingers tracing the lightweight fabric, feeling its seemingly inadequate construction compared to the thicker military blankets of the Imperial Japanese Army.

A smirk crossed his face as he turned to Captain Masaruito, a fellow officer captured during the same operation. “The Americans expect us to survive their winter with this?” Tanaka whispered in Japanese, contempt evident in his voice. “Their industrial might seems greatly exaggerated if this is the best they can produce.”

Captain Ido nodded in agreement, having been raised on stories of American weakness and industrial inferiority. For years, imperial propaganda had portrayed Americans as soft, decadent people, incapable of producing quality military goods. The Japanese military leadership had consistently emphasized that American products were cheaply made, mass-produced items lacking the careful craftsmanship and durability of Japanese equivalents.

The thin blanket seemed to confirm everything they had been told. What Lieutenant Tanaka couldn’t possibly comprehend in that moment was how this simple blanket would soon shatter 20 years of carefully constructed beliefs about American manufacturing capabilities. Within 72 hours, as temperatures plummeted across the Kansas plains to well below freezing, Tanaka would experience a revelation that would fundamentally alter his understanding of the war, his enemy, and ultimately why Japan could never have won against the United States of America. What he saw that night defied two decades of indoctrination, and the truth was woven into the very fabric he had so quickly dismissed.

The journey that brought Lieutenant Tanaka to this revelation began long before his capture. Throughout the 1930s and early 1940s, the Japanese government had carefully cultivated a national mythology about the inherent superiority of Japanese spirit, craftsmanship, and military prowess. Schools, newspapers, and military training all reinforced the narrative that while Western nations might possess raw materials in greater quantities, they lacked the discipline, spirit, and ingenuity of the Japanese people. This belief was central to the Japanese military strategy. Quality would overcome quantity, and the fighting spirit of Japanese soldiers would prevail against materially superior forces.

Military propaganda specifically targeted American industrial capacity as a paper tiger. Impressive in raw numbers but producing inferior goods. Official military publications distributed to officers like Tanaka claimed American factories prioritized speed over quality, resulting in weapons that would fail, vehicles that would break down, and equipment that would deteriorate rapidly under combat conditions. One widely circulated military manual from 1941 stated, “American industry produces in quantity what Japanese craftsmanship creates in quality. Their tanks may outnumber ours 5 to one, but will fail in battle conditions where Japanese tanks prevail.” This narrative was reinforced by carefully selected intelligence reports highlighting American equipment failures while suppressing information about successful American military operations.

Japanese military observers who had visited the United States in the 1930s were encouraged to report on labor disputes, production inefficiencies, and quality control issues while minimizing the sheer scale of American manufacturing capabilities. By 1943, when Tanaka was captured, this distorted view had been deeply ingrained in the Japanese military consciousness. Few officers or soldiers questioned the official narrative that American industrial output, while numerically impressive, was qualitatively inferior to Japanese production. This belief shaped military planning at every level, from strategic decisions to tactical approaches on the battlefield.

The reality, of course, was dramatically different. By 1943, American industrial output had reached staggering levels that Japanese military planners had considered mathematically impossible. In 1941, President Roosevelt had called for the production of 50,000 aircraft per year, a number Japanese intelligence officers dismissed as propaganda. Yet by 1943, American factories were producing nearly 100,000 aircraft annually, more than six times Japan’s maximum output. Similarly, while Japan struggled to replace sunken warships, American shipyards were launching a new vessel almost daily.

What made this industrial miracle even more remarkable was that the quality of American goods had not been sacrificed for quantity, as Japanese propaganda had insisted would happen. In fact, American manufacturing had achieved what seemed paradoxical to Japanese military thinking. Mass production methods had actually improved quality through standardization, rigorous testing, and continuous refinement of designs.

Lieutenant Tanaka knew none of this as he examined his seemingly inadequate American blanket on that cold December day. To him, the thin fabric represented exactly what he expected: American corner-cutting and inferior manufacturing. He had no way of knowing that the blanket he held was the product of a revolutionary textile manufacturing process that Japanese industry could not match. Using synthetic fibers developed through research programs costing millions of dollars, the blanket was actually a military-grade thermal insulation product developed specifically for high-altitude bomber crews operating in temperatures as low as -50°F.

It utilized a multi-layer construction with trapped air pockets that provided insulation far superior to traditional wool blankets of twice the thickness. The manufacturing process required precision equipment that could produce microscopic fiber alignments to maximize heat retention while minimizing weight and bulk. Technology that simply did not exist in the Japanese industrial arsenal.

This technological gap was representative of a broader reality that Japanese military intelligence had either failed to grasp or deliberately concealed from officers like Tanaka. American industry was not merely larger than Japan’s, but operated at a level of technological sophistication that Japanese manufacturing could not approach. The thin blanket that Tanaka dismissed as inferior represented not American weakness, but a devastating technological advantage.

That night, as temperatures dropped rapidly across the Kansas plains, Lieutenant Tanaka prepared for a night of discomfort. He layered both his uniform and the American-issued clothing, expecting the thin blanket to provide minimal protection against the bitter cold. As he settled onto his bunk, he arranged the blanket skeptically, already rehearsing in his mind how this experience would confirm Japanese propaganda about American manufacturing deficiencies.

“These Americans cannot even produce a proper winter blanket,” he muttered to himself as the lights in the barracks dimmed for the night. “How did they ever think they could defeat the Empire of Japan?”

As the temperature continued to fall outside, dropping to 15°F, Tanaka waited for the inevitable chill to penetrate his meager covering. An hour passed, then to his surprise, he felt no cold penetrating through the thin American blanket. In fact, his body heat seemed to be reflecting back to him, creating a cocoon of warmth that defied the blanket’s apparent thinness. He reached a hand out from beneath the covering and felt the frigid air of the barracks, then quickly withdrew it back into the unexpected warmth beneath his supposedly inadequate American blanket.

Confused, Tanaka sat up and examined the blanket more carefully in the dim light. The material felt unlike anything he had encountered in Japan. Not quite wool, not quite cotton, but something entirely different. The weave pattern was incredibly tight and consistent with a uniformity that spoke of precision manufacturing rather than the inferior construction he had expected.

“Itto,” he whispered to his fellow officer in the next bunk. “Are you cold?”

“No,” came the surprised reply. “This blanket, it is much warmer than it appears.”

Their conversation was interrupted by Sergeant Kenji Watanabi, who had been listening from three bunks away. “The Americans gave us their worst blankets,” Watanabi insisted, though his voice lacked conviction. “They would not waste good materials on prisoners.”

Lieutenant Tanaka nodded in agreement, unwilling to contradict the expected narrative. Yet, doubt had begun to creep into his mind. If Americans considered these remarkably effective thermal blankets to be suitable for prisoners, what kind of blankets did their own soldiers receive? And what did that imply about American industrial capacity?

The next morning, Tanaka observed the American guards patrolling the camp perimeter. They wore uniform winter clothing that appeared standardized and well-constructed. Every guard had identical gloves, boots, and outerwear, a level of equipment standardization that the Japanese military had never achieved even for elite units. In the Imperial Army, equipment quality varied widely between units, with elites receiving the best, while ordinary infantry often made do with substandard gear. Yet here, even the guards of a prisoner camp in the middle of America seemed equipped to a standard that would impress Japanese frontline commanders.

As days passed, Lieutenant Tanaka began noticing other details that contradicted his preconceptions. The camp’s kitchen produced meals with ingredients that had become rare luxuries in Japan by 1943. Fresh meat, eggs, milk, and fruit appeared regularly. More surprisingly, the portions seemed unaffected by rationing, with food waste being a common occurrence. Tanaka watched in disbelief as American kitchen staff discarded more food in a single meal than a Japanese civilian family might receive in a week of rationing.

“This must be a show,” Tanaka remarked to Captain Ido, mentioning his observations. “How are they trying to demoralize us by displaying artificial abundance?”

Yet, as weeks turned into months, the artificial abundance never diminished. It became clear that the American guards and staff considered the provisions entirely normal and unremarkable. This was not a show put on for prisoners. This was simply the standard American wartime experience, a reality so far removed from conditions in Japan that Tanaka struggled to reconcile it with his understanding of the war.

The most revealing moment came in February 1944 when Tanaka was assigned to a work detail in the camp’s supply warehouse. There he saw hundreds of the same thermal blankets stacked in crates labeled as standard-issue P allocation. Next to these crates were others containing what appeared to be newer versions of the same blanket marked “infantry standard North European theater.” The implication was clear. The blankets issued to Japanese prisoners were not exceptional items, but standard mass-produced goods considered suitable for captured enemy personnel. The true combat blankets, presumably of even higher quality, were reserved for American troops fighting in Europe.

Tanaka’s attention was drawn to a shipping manifest left carelessly on a desk. Though his English was limited, he could make out production figures and distribution allocations. The document indicated that the manufacturer, Anderson Textile Mills of North Carolina, was producing over 75,000 thermal blankets monthly. And this was just one of 17 facilities listed as producing similar items. The scale was difficult to comprehend. The entire Japanese textile industry at its wartime peak could not match the output of the single American factory.

The conversation with Private Nakamura, a former industrial engineer at a textile factory in Osaka, marked the beginning of a profound shift in Tanaka’s understanding of the war. The blanket, initially dismissed as evidence of American inferiority, had instead become the first crack in the foundation of beliefs upon which his military worldview had been built. If American industry could casually provide prisoners of war with equipment that Japan’s best factories couldn’t produce for its own elite troops, what did that suggest about the broader industrial disparity between the two nations?

The revelation about the blankets was just the first in a series of discoveries that would systematically dismantle Tanaka’s preconceptions about American industrial capacity. The war had been lost before it began. Japan had initiated conflict against a nation whose industrial capacity so vastly exceeded its own that no strategy, no tactical brilliance, no fighting spirit could overcome the fundamental material disparity.

The thin American blanket had been the first sign. What Tanaka had once scorned as a symbol of American weakness had become a powerful symbol of Japan’s fundamental misunderstanding of its enemy. By the end of 1944, the truth was undeniable: America’s industrial might was a force that Japan could not defeat, and its extraordinary manufacturing capacity would determine the outcome of the war. And it was in the simplest of objects—a blanket—that Lieutenant Tanaka first saw the truth.

Note: Some content was generated using AI tools (ChatGPT) and edited by the author for creativity and suitability for historical illustration purposes.