America Had No Aircraft Aluminum in 1941 — So the U.S. Learned to Build Bombers From Scrap .NU

America Had No Aircraft Aluminum in 1941 — So the U.S. Learned to Build Bombers From Scrap

December 7th, 1941. Pearl Harbor burning. 24,43 Americans dead. The Pacific Fleet crippled. Within hours, President Roosevelt would ask Congress for a declaration of war. But in a windowless office deep inside the War Production Board headquarters in Washington, DC, a different kind of panic was unfolding.

Not about ships or soldiers or strategy, about metal. Specifically, about the one metal that made modern air power possible. Aluminum, the lightweight miracle that turned canvas biplanes into all metal bombers capable of carrying 10,000 lb of ordinance across an ocean. America’s entire war plan depended on building 50,000 aircraft per year.

Each B17 flying fortress required 14,000 lb of aluminum. HB24 Liberator 17,500 lb. Do the math. America needed roughly 600 million pounds of aircraft grade aluminum per year to meet production targets. Current capacity in December 1941, 287 million, less than half. And that number assumed perfect efficiency, zero waste, and no competing demands from tanks, trucks, ships, and landing craft.

all of which also needed aluminum. The shortage wasn’t absolute. America had aluminum smelters. Alcoa, the aluminum company of America, had been producing aluminum since 1888. But there’s aluminum and then there’s aircraft aluminum. The difference between those two things would determine whether American bombers could reach Berlin or whether they’d tear apart in midair trying.

This is the documented story of how America created an entire secondary aluminum industry from nothing, built the world’s largest metal recycling network in 18 months, and invented new alloys that were stronger than what they replaced. All while Germany’s aluminum production, which had started the war with a massive advantage, collapsed under its own strategic mistakes.

Let’s start with what most people don’t understand about aluminum. Pure aluminum is useless for aircraft. It’s too soft. You can bend it with your hands. A wing made from pure aluminum would fold under aerodynamic stress before the plane left the runway. What makes aluminum useful for aviation are alloys.

Mixtures of aluminum with small percentages of other metals that transform its properties. The critical alloy in 1941 was called 24ST, later redesated 2024. The formula 93.5 aluminum, 4.4 four copper, 1.5 magnesium, 0.6 manganese. That specific combination created a material with tensil strength of 64,000 lb per square in comparable to structural steel, but at 1/3 the weight, could be riveted, bent, formed into complex shapes, and it didn’t corrode rapidly in salt air.

Every American combat aircraft from the P38 Lightning to the B29 Superfortress was built primarily from 24 ST aluminum alloy. But creating 24 ST required more than just mixing metals. The copper had to come from specific sources free of impurities that weakened the alloy. The magnesium had to be precisely measured.

Too little and the material was brittle. Too much and it became prone to stress corrosion cracking. The heat treatment process, solution heat treatment followed by artificial aging, had to be controlled within narrow temperature ranges or the metal lost its strength. In 1941, only a handful of American facilities could produce aircraft grade aluminum alloy sheet to the tolerances required.

Alcoa’s plants in Pennsylvania, Tennessee, and Washington state. Reynolds Metals a much smaller competitor, and that was essentially it. The bottleneck wasn’t raw aluminum. Box site, the ore from which aluminum is extracted, was plentiful. America had domestic sources in Arkansas and Alabama, plus imports from British Gana and Dutch Gana, both Allied controlled.

The bottleneck was refining capacity. Converting boite into pure aluminum requires enormous amounts of electricity. The Hallerald process invented in 1886 involves dissolving aluminum oxide in molten kryolite at 960° C and passing massive electrical current through it. One pound of aluminum requires roughly 7 kowatt hours of electricity.

To produce 600 million pounds per year meant generating and delivering over 4 billion kwatt hours of electricity annually just for aluminum production. That’s more electrical power than the entire city of New York consumed in 1941. The other bottleneck was the alloying and rolling mills. Taking pure aluminum ingots and converting them into sheet metal of precise thickness with uniform alloy composition free of defects required specialized equipment.

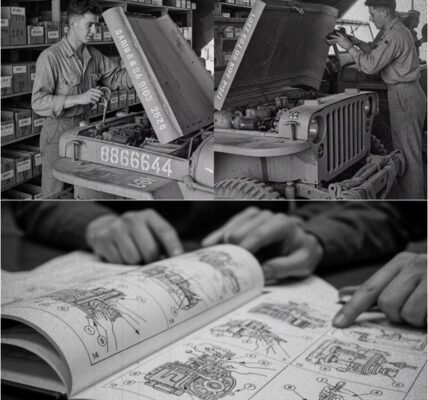

Rolling mills capable of producing sheet aluminum thin enough for aircraft skins, typically 0.020 to 0.032 in thick, were rare. Each mill cost millions of dollars and took over a year to build. On December 8th, 1941, the day after Pearl Harbor, William Nudson, director of the Office of Production Management, later reorganized as the War Production Board, convened an emergency meeting with Alcoa executives, military procurement officers, and metallurgical engineers from Wrightfield in Dayton, Ohio.

The question on the table was brutallysimple. Can America build 50,000 aircraft per year with current aluminum capacity? The answer from Alcoa’s chief engineer recorded in meeting minutes declassified in 1973 was equally blunt. Not unless we find another 300 million pounds per year from somewhere. New smelters will take 18 to 24 months to build.

Assuming we can secure the electrical capacity, which is uncertain, we either reduce aircraft production targets, which the military won’t accept, or we find aluminum that doesn’t require smelting. That phrase, aluminum that doesn’t require smelting, became the foundation of America’s solution because there was one vast source of aluminum that could be accessed immediately without building new smelters or rolling mills.

Aluminum that had already been refined, alloyed, and formed scrap. In 1941, America had been using aluminum in consumer products for over three decades. cooking pots and pans, lawn furniture, window frames, automobile parts, electrical fixtures, sporting goods, and thousands of other applications. All of that aluminum sitting in homes, junkyards, and warehouses across the country could theoretically be reclaimed and remelted into aircraft alloy.

But nobody had ever attempted metal recycling on the scale required. The logistics were staggering. Aluminum scrap was dispersed across 130 million people in 48 states. It had to be collected, transported, sorted by alloy type because mixing incompatible alloys created unusable material, cleaned of paint, grease, and contamination, and delivered to remelting facilities that didn’t yet exist in sufficient quantity.

And it had to happen fast because aircraft production couldn’t wait. On January 12th, 1942, exactly 36 days after Pearl Harbor, the War Production Board launched the National Aluminum Scrap Drive. It was the largest coordinated civilian mobilization for material collection in American history. The program had three components.

Component one, consumer collection. Civilians were asked to turn in aluminum items at designated collection points. Schools, fire stations, post offices, and municipal buildings became dropoff locations. Boy Scout troops organized neighborhood collection drives going doortodoor with wagons. The incentive was patriotism, not money.

Posters appeared nationwide showing bombers with the caption, “Your aluminum pots are flying over Berlin. Women’s organizations, church groups, and civic clubs competed to collect the most aluminum. In the first 6 weeks, civilians turned in over 11 million pounds of aluminum cookware, lawn chairs, and household items. By June 1942, the total exceeded 70 million.

But this created an immediate problem. Much of the aluminum collected was unsuitable for aircraft. Aluminum cookware was typically made from alloy 3003 which contains manganese but lacks the copper and magnesium necessary for structural strength. Lawn furniture often used alloy 50-52 which has magnesium but no copper.

These alloys couldn’t be simply remelted into 24 aircraft alloy. Mixing them created unpredictable properties and weakened the final material. The solution required chemistry and industrial sorting on a scale never attempted. Component two, industrial scrap reclamation. Manufacturing plants, machine shops, and fabrication facilities generated enormous quantities of aluminum scrap during normal production.

Every time a sheet of aluminum was cut, stamped, or drilled, waste was created. Trimmings, turnings, rejected parts, defective castings. In peace time, much of the scrap had been discarded or sold to small-scale scrap dealers with no systematic tracking. The War Production Board issued General Order L27 in February 1942, requiring all industrial facilities working with aluminum to segregate scrap by alloy type and report it to regional collection centers.

Penalties for non-compliance included loss of priority materials allocations, effectively shutting down factories within 3 months. Industrial scrap collection networks were operating in every major manufacturing center. Detroit, where automobile production had converted to military vehicles, became the largest single source.

Aircraft manufacturers themselves were wasteful. In 1941, roughly 35 of aluminum sheet used in aircraft production ended up as scrap due to cutting, forming, and rejected parts. Reducing that waste percentage became a priority. Engineers redesigned parts to minimize material use. Nesting patterns, the arrangement of parts on a sheet to maximize utilization, were optimized through mathematical analysis.

By late 1942, waste had been reduced to 22, saving over 40 million pounds of aluminum annually, component 3, automotive and industrial salvage. America had roughly 32 million automobiles on the road in 1941. Each car contained aluminum components, engine blocks in some models, pistons, carburetors, transmission housings, wheels.

As vehicles reached end of life or were scrapped due to gasoline rationing, those aluminum components becamerecovery targets. The War Production Board established a nationwide network of authorized scrap dealers who were required to separate aluminum from steel, copper, and other metals. Junkyards that had previously piled wrecked cars indiscriminately now had to disassemble them systematically.

Aluminum parts were stripped, sorted, and shipped to regional collection centers. By mid 1942, automotive salvage was contributing 15 million pounds of aluminum per month. But collecting scrap was only half the problem. The other half was converting mixed alloy scrap into usable aircraft aluminum.

This required metallurgical innovation because traditional remelting simply didn’t work. Here’s why. If you take 100 lb of aluminum alloy scrap containing various percentages of copper, magnesium, manganese, silicon, and other elements, melt it down and pour it into ingots, you get an alloy with unpredictable composition. The copper percentage might be 2.1.

It needs to be 4.4. The magnesium might be 0.8. It needs to be 1.5. Using that material in aircraft would be catastrophic. A wing spar with insufficient copper content might fail under load causing structural failure in flight. The solution was called secondary aluminum production. Distinct from primary aluminum which is smelted from boxite or secondary aluminum production involved taking mixed scrap, analyzing its composition through spectrographic analysis and then adding measured quantities of pure copper, magnesium and

manganese to bring the alloy back to 24 ST specifications. The process required new facilities. In January 1942, America had 14 secondary aluminum smelters capable of processing aircraft grade alloy. By December 1942, there were 47 with total capacity of 480 million pounds per year. The largest facility was built by the Defense Plant Corporation in St. Louis.

Construction began in March 1942 and was completed in September, 7 months. The plant could process 60 million pounds of scrap aluminum annually, converting it into certified aircraft grade alloy sheet. The technical challenge was maintaining quality control. Primary aluminum from Alcoa smelters came with guaranteed composition because it was produced from controlled raw materials.

Secondary aluminum made from scrap was inherently variable. Every batch had to be tested. Wrightfield developed a rapid spectrographic testing procedure that could analyze alloy composition in 12 minutes instead of the previous 3-hour chemical analysis method. This allowed realtime adjustment of alloy additions during melting.

But even with secondary smelters operating at full capacity, America still faced a shortfall. The numbers in June 1942 looked like this. Primary aluminum production 340 million pounds per year and rising as new smelters came online. Secondary aluminum from scrap 180 million per year. Total available aluminum 520 million per year required for 50,000 aircraft 600 million shortfall 80 million.

That 80 million pound gap forced the third solution. Material substitution and alloy innovation. Engineers at Wrightfield and the National Bureau of Standards began investigating whether aluminum could be replaced in certain applications. The results were mixed. Steel could replace aluminum in some structural components, but weight penalties were severe.

A B17 wing spar made from steel instead of aluminum added 840 lbs to the aircraft, reducing bomb load and range. Magnesium alloys were lighter than aluminum but more expensive and harder to machine. They were used selectively in engine components but couldn’t replace aluminum for primary structures. Wood was considered.

The British De Havland Mosquito Bomber was built largely from plywood and performed excellently, but American production infrastructure was optimized for metal, not wood. Switching would delay production by months. The breakthrough came not from replacing aluminum, but from using it more efficiently. Metallurgists at Alcoa, working with Air Force engineers, developed a new alloy designated 75s, later redesated 7075.

The formula was radical. 90 aluminum, 5.6 zinc, 2.5 magnesium, 1.6 copper, 0.23 chromium. The zinc addition was controversial because zinc aluminum alloys had a reputation for stress corrosion cracking in marine environments. But controlled testing showed that with proper heat treatment, 75s offered tensil strength of 83,000 psi, nearly 30 stronger than 24 st.

That strength advantage meant aircraft structures could use thinner aluminum sheet, reducing weight and aluminum consumption without sacrificing strength. The B29 Superfortress, which entered production in 1943, was the first aircraft designed from inception to use 75s alloy in wing spars and fuselage frames. The weight savings compared to equivalent 24 ST structures was 1,240 lb per aircraft.

And the aluminum savings was 1,680 lb per aircraft. Multiply that by 3,970 B29s built and you get over 6.6 million lb of aluminum saved through alloy innovation alone. But 75s had alimitation. It required zinc and America didn’t produce much zinc domestically. Most zinc came from Mexico, Peru, and Canada.

Securing zinc supplies required diplomatic negotiations and priority shipping allocations. The War Production Board established zinc as a strategic material in April 1942, restricting its use to military applications. By early 1943, the aluminum crisis had been solved through the combination of all three approaches. New primary smelters coming online adding 180 million pounds of annual capacity.

Secondary aluminum from scrap contributing 210 million pounds annually. Material efficiency through new alloys and reduced waste saving 90 million annually. Total aluminum available by mid 1943 820 million per year exceeding the 600 million target. American aircraft production in 1943 85,898 aircraft 1944 96,318 aircraft 1945 even with the war ending in August 46,01 aircraft through midyear.

Total World War II production 300,317 aircraft more than Germany, Britain, Japan and the Soviet Union combined. But those numbers hide the real story, which is about the people who made it happen. Because aluminum doesn’t smelt itself, scrap doesn’t sort itself, and alloys don’t innovate themselves. At the Reynolds Metal Secondary Smelter in Louisville, Kentucky, the workforce in January 1942 was 340 people, 89 male.

By August 1942, it was 1,847 people, 64 female. Mary Kowalsski, age 22, had been a department store clerk before the war. In March 1942, she was hired at Reynolds to operate a spectrographic analyzer, a precision instrument that required understanding wavelength spectroscopy and alloy chemistry.

Her training consisted of two weeks of classroom instruction followed by supervised operation. By June, she was running the analyzer independently, testing 40 samples per shift. In a 1988 oral history interview, she recalled, “They showed us these charts with colored lines, and you had to match the pattern to know what metals were in the sample.

If the copper line was too low, you reported it, and they’d add more copper to the melt.” I didn’t understand the science at first, but I understood that if I made a mistake, some pilot might die because his wing fell off. After a while, you stop thinking about how complicated it is and just do the work.

The secondary smelters operated 24 hours a day, 7 days a week. The heat was brutal. Furnaces ran at 750° C. Summer temperatures inside the plants exceeded 120° F. Workers on the melting floor rotated every 30 minutes to avoid heat exhaustion. Coal and electricity shortages periodically forced production cuts.

In winter 1943, a coal shortage in Louisville shut down the Reynolds plant for 6 days. The backlog took 3 weeks to clear. Meanwhile, the scrap collection system created its own challenges. In small towns across America, volunteer committees organized aluminum drives with religious fervor. In Mansfield, Ohio, the local women’s club collected 14,000 lbs of aluminum in one weekend in April 1942.

Housewives contributed cake pans, coffee percolators, and ice cube trays. One woman donated her deceased husband’s artificial leg, which had an aluminum frame. But not everything collected was usable. Aluminum foil, widely collected with great enthusiasm, was nearly worthless. The thin foil oxidized rapidly and was contaminated with food residue.

Cleaning and remelting it consumed more energy than it saved. By late 1942, collection drives were instructed to stop accepting foil. Painted aluminum was another problem. Many consumer items had been painted or coated. The paint had to be removed before melting or it contaminated the alloy. Sand blasting was effective but slow.

Chemical stripping was faster but required costic solutions and created hazardous waste. Some facilities simply burned off paint in incinerators, contributing to local air pollution that was tolerated as necessary for the war effort. The railroad system struggled to handle the scrap flow. Aluminum scrap had low density.

A box car filled with aluminum scrap weighed far less than one filled with steel or coal, making it economically inefficient to transport. The War Production Board issued priority shipping orders requiring railroads to move aluminum scrap ahead of lower priority freight regardless of profitability. By mid 1943, over 1,200 rail cars per week were dedicated to aluminum scrap transport.

The entire system was a logistical marvel built in months. From rural collection points to regional sorting centers to secondary smelters to rolling mills to aircraft factories, every step was tracked. Serial numbers were assigned to batches of scrap. Chemical composition was recorded at every stage. Finished aluminum sheet carried certifications traceable back to the scrap sources.

This level of material tracking was unprecedented in civilian industry and became the foundation for modern supply chain management. But America’s aluminum success wasn’t just about productionvolume. It was about the efficiency of use. And that’s where Germany failed. Germany entered World War II with significant aluminum advantages.

German aluminum production in 1939 was roughly 340 million pounds per year, comparable to the United States. Germany also had access to Norwegian hydroelectric power, which fueled additional smelters after the 1940 invasion. By 1943, Germany was producing approximately 480 million pounds of aluminum annually. But Germany’s aircraft production peaked at 39,87 aircraft in 1944, less than half of American output that same year.

Why the discrepancy? Because Germany wasted aluminum. The Luwaffa’s aircraft designs prioritize performance over production efficiency. The Messormmit BF 109, Germany’s primary fighter, used complex formed aluminum structures that required extensive hand fitting. Rejected parts rates in German factories averaged 31, compared to 22 in American plants by 1943.

More critically, Germany never developed an effective scrap reclamation system. Aluminum scrap in German factories was often melted down locally without proper alloy control, creating substandard material that weakened aircraft. There was no national coordination, no standardized testing, and no systematic tracking.

German aircraft suffered mysterious structural failures that postwar analysis attributed to inconsistent aluminum quality. The German aviation industry also fragmented production across hundreds of small facilities to reduce vulnerability to bombing. This dispersion made quality control nearly impossible. A wing manufactured in one location might use different aluminum specifications than a fuselage from another, creating assembly problems.

Albert Spear, Germany’s Minister of Armaments, noted in his postwar memoir, Inside the Third Reich, that aluminum shortages became critical by late 1944, not because Germany lacks smelting capacity, but because the distribution and quality control systems had collapsed. By contrast, American aluminum production was centralized, standardized, and obsessively tracked.

The war production board issued mandatory specifications for every aluminum alloy. Right field tested random samples from every smelter monthly. Failures resulted in facility shutdowns until problems were corrected. The result was consistent, reliable material. American pilots trusted their aircraft because American engineers trusted their aluminum.

The Pacific War added another dimension to the aluminum challenge. Operating in tropical environments with high humidity and salt exposure accelerated aluminum corrosion. The 24ST alloy, which performed well in European conditions, showed stress corrosion cracking in the Pacific theater within months. Engineers at Wrightfield developed improved corrosion resistant treatments.

Alclad, a thin layer of pure aluminum bonded to 24 ST sheet, provided corrosion protection without sacrificing strength. By 1944, all aircraft destined for Pacific operations used alclad aluminum as standard. The material science innovations forced by wartime necessity had permanent impacts. After the war, 7075 aluminum alloy became the standard for commercial aviation.

Every Boeing, Douglas, and Lockheed airliner built from 1950 through the 1980s used 7075 as the primary structural material. Modern aircraft still use alloys descended directly from wartime innovations. The recycling infrastructure built for war became the foundation of America’s modern recycling industry. Secondary aluminum production, which barely existed before 1941, became a permanent sector.

Today, roughly 75 of all aluminum ever produced is still in use, recycled repeatedly. That circular economy began in 1942 when America learned to turn pots and pans into bombers. But the story isn’t just about metal. It’s about what that metal represented. When civilians turned in their aluminum cookware, they weren’t just donating metal.

They were participating in the war effort in a tangible, personal way. Every housewife who gave up her cake pan believed correctly that she was helping build the aircraft that would win the war. That psychological connection between home front and battlefront was as important as the aluminum itself. It created a national unity of purpose that transcended politics, class, and region.

The aluminum drives were visible participatory patriotism. In December 1943, an American B17 crew stationed in England named their bomber Aluminum Overcast. The nose art featured a housewife pouring a pile of pots and pans from heaven onto German cities. The crew painted tally marks on the fuselage after each mission.

By war’s end, they had flown 32 combat missions. In their final mission report, pilot Lieutenant James Harrison wrote, “Every time we took flack over Germany, I thought about the people back home who gave up their aluminum so we could be here. That kept me focused. We weren’t just flying a machine.

We were flying the will of a whole nation. America entered World WarII with an aluminum deficit that should have been crippling. The numbers didn’t work. The capacity wasn’t there. The infrastructure was inadequate. But through a combination of industrial scaling, material science innovation, and nationwide civilian mobilization, America turned shortage into abundance in less than 2 years.

from 287 million pound of capacity in December 1941 to over 820 million by mid 1943. From wasteful production methods to optimized efficiency, from disposable consumer culture to systematic recycling. The transformation wasn’t accidental. It was engineered. The War Production Board didn’t hope scrap would appear. They organized collection networks.

Alcoa and Reynolds didn’t wait for someone to invent better alloys. They hired metallurgists and gave them labs. Wrightfield didn’t accept structural failures. They tested every batch until they understood why. By the time the war ended in August 1945, American aluminum production capacity exceeded 1.1 billion pounds per year.

Aircraft plants had aluminum stockpiles sufficient for months of production. The shortage that had seemed existential in 1941 had become abundance by 1945. Germany, which started the war with aluminum parody, ended it with chronic shortages, grounded aircraft, and crumbling industrial capacity. The difference wasn’t resources.

Germany had boxite access through occupied territories. The difference was systems. America built an integrated production, recycling, and quality control system that functioned under pressure. Germany never did. After the war, the aluminum industry didn’t collapse. It converted to civilian production. The smelters built to make bombers made cookware, automobiles, and eventually beverage cans.

The secondary smelters continued operating, processing scrap that in previous generations would have been landfilled. The engineering workforce trained under wartime urgency became the foundation of post-war aerospace and material science industries. When you open an aluminum can today, you’re touching metal that’s been recycled an average of 13 times.

That can might contain aluminum that was originally a B17 wing or a housewife’s cake pan from 1942 or a 1955 Chevrolet engine block or a 1987 commercial airliner or 10 other incarnations. Aluminum doesn’t degrade through recycling. It’s infinitely reusable. That reality that metal has memory and permanence is the legacy of 1942.

Before the war, America treated aluminum as disposable. After the war, we understood it was too valuable to waste. The transformation wasn’t just industrial. It was cultural. We learned that scarcity doesn’t mean defeat. It means innovation. We learned that national mobilization isn’t about central planning alone. It’s about engaging every citizen in the effort.

We learned that engineering isn’t just about designing better machines. It’s about designing better systems, better logistics, better ways of thinking about resources. In 1941, America had no aircraft aluminum, or rather not enough. By 1943, we had more than anyone in the world.

The difference between those two states wasn’t luck or resources alone. It was will. The will to collect scrap doortodoor. The will to build 47 new smelters in 18 months. The will to trust women with spectrographic analyzers. The will to invent new alloys under deadline pressure. The will to turn household junk into strategic advantage.

That will more than any single technology or resource is what built the arsenal of democracy. Aluminum didn’t win the war by itself. But without aluminum, the war couldn’t have been won. Every bomber over Berlin flew because someone in Louisville melted scrap correctly. Every fighter in the Pacific flew because someone in Pennsylvania rolled aluminum sheet to precise thickness.

Every transport over the Himalayas flew because metallurgists in Ohio invented stronger alloys. The war ended. The bombers stopped flying. But the aluminum remained, cycling through the economy generation after generation. A permanent legacy of the moment when America learned that scarcity is temporary, but ingenuity is renewable.

When you see an aluminum baseball bat, a soda can, or an aircraft wing, you’re seeing the descendants of 1942. You’re seeing proof that crisis doesn’t destroy capacity. It reveals it. America had no aircraft aluminum in 1941. By 1945, we had taught the world how to build an industry from scrap.

That’s the power of necessity meeting engineering, of civilian will meeting industrial capacity, and of a nation discovering that the metal it needed was already in its kitchens waiting to Why?